Can you quantify how mechanical forces affect your line efficiency?

Increase efficiency by isolating and resolving the root cause of damage, breakage and performance loss caused by impact and pressure on containers.

Packaging engineers have to keep the line running, while also keeping focus on efficiency targets and Continuous Improvement initiatives. Dealing with today’s breakage and damage while looking to find

long-term efficiencies is difficult without the right tools to uncover the unknowns of the line.

Pinpoint the Root Cause of Damage

In minutes, find the root cause of problems affecting your line using sensor data that measures exactly what your container is experiencing.

• Quick-check the line within an hour

• Receive data from entire line to determine root cause

• Pinpoint and visualize the exact location where product damage occurs.

• Train the entire team to respond to downtime or critical events

• Validate the effectiveness of the fix

Efficiency Improvements

Increase efficiency by isolating and resolving the root cause of damage, breakage and performance loss caused by impact and pressure on containers.

• Understand how underlying pressure, impact and vertical load

issues affect various container types and materials

• Increase line speed by correcting problematic areas

• Eliminate guesswork or trial and error corrections

• Minimize unplanned downtime

• Test equipment variables

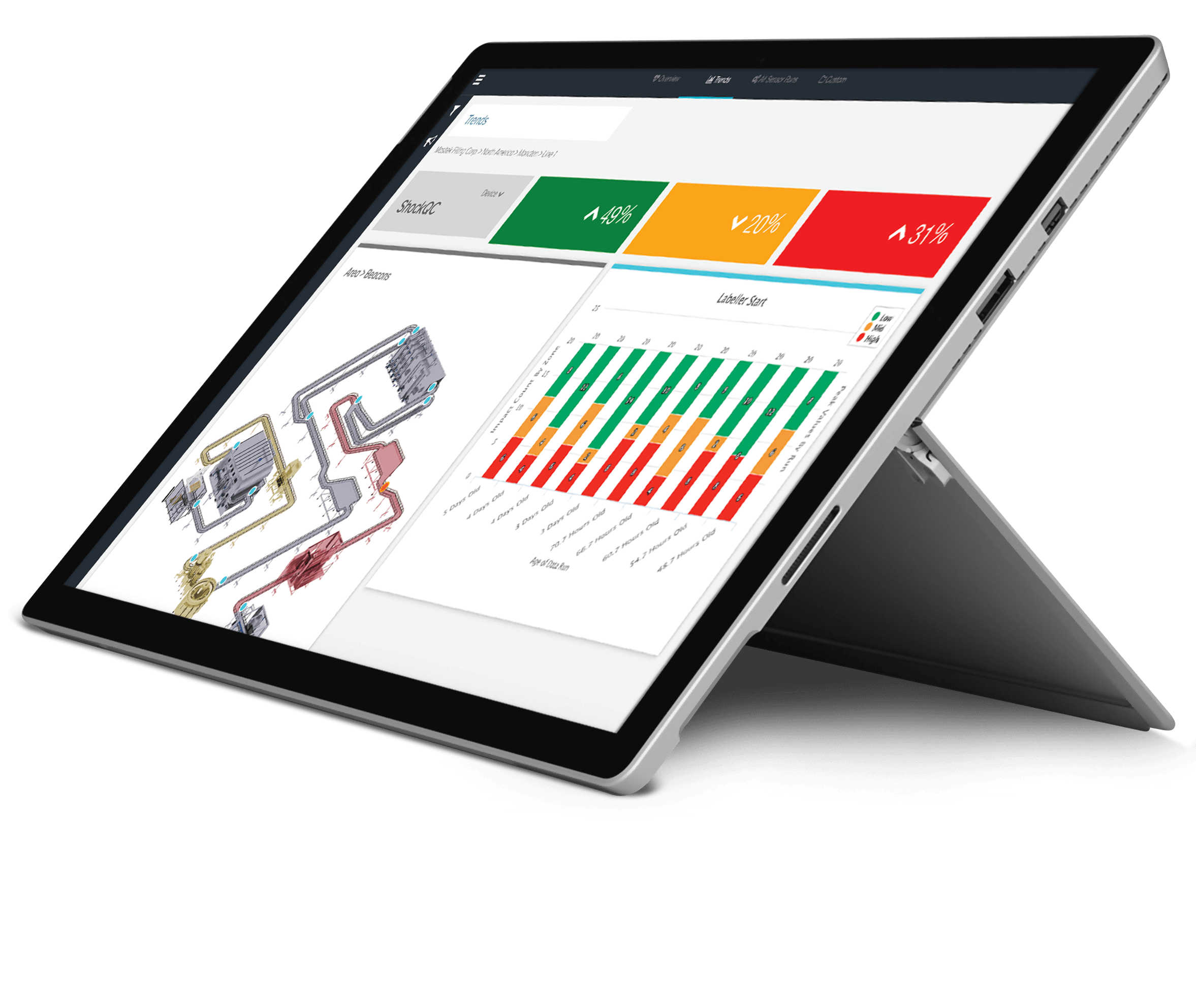

CI Validation & Preventative Maintenance

Validate Continuous Improvement initiatives and prevent performance drift, unplanned maintenance or catastrophic events through comparative data analysis.

-

Benchmark performance and compare run history

-

Identify trends and correct escalating issues before they become catastrophic

-

Make data-driven maintenance decisions

-

Validate the effectiveness of CI initiatives

-

Test maintenance variables

In-Line Sensors for Line Efficiency

Case Study

Carlsberg uses smart sensors globally to pinpoint breakage.

Industries

Containers

Find the source

of packaging damage

on the line.