Why In-Line Sensors for the Wine Industry?

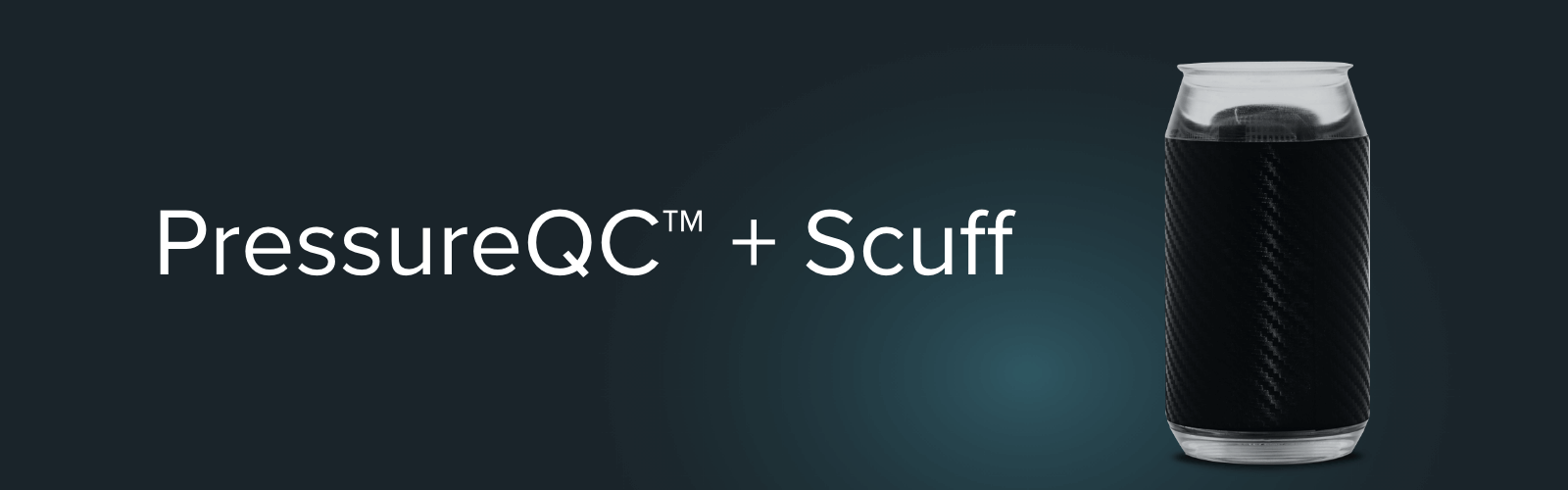

Under pressure to execute flawless bottles and ideal corking levels, wine production is a competitive category. Scuffing and impact damage as well as long calibration times cause losses and costly downtime.

Sensors help prevent costly aesthetic damage to bottles and labels.

Wine bottling is a competitive category, with a time consuming, high-value product and uncompromising consumers. Damage caused to glass bottles by scuffing can not only damage brand image if missed by quality control but can also cause loses in both production time and product..

Optimize downward corking pressure for a perfect seal.

Proper corking and a perfect seal require optimal downward pressure. Wine producers require full control of their bottling line and corking machines to limit breakage, mechanical or product damage and leakage. Spending excessive amounts of time calibrating a line can lead to increased downtime and will not guarantee the integrity of the product.

Using smart in-line sensors allows downward pressure to be monitored – minimizing the time required for calibration and increasing efficiency.

Reduce bottle breakage – a major cost of downtime in the wine bottling industry.

To optimize output, wine producers are under pressure to increase the speed of production and quickly accommodate new bottle designs. This can lead to an increase in bottle breakage and associated line downtime, as well as shortening bottle lifespan. Advances in technology provide instant measurement of bottle acceleration and performance on the line, reducing breakage by up to 80%.

In-Line Sensors for the Wine Industry

Case Study

Carlsberg uses smart sensors globally to pinpoint breakage.

Applications

Containers

Find the source

of packaging damage

on the line.