Soda & water bottling operations can achieve significant cost savings by reducing damaging mechanical forces on the line.

The pressure is on soft drink and bottled water companies to produce more and spend less. Increasing line speed can lead to many issues, including torn labels, improper capping and sealing, denting and breakage; particularly in lightweight products.

By understanding, measuring and locating the following forces on the line, filling operations can identify gaps and problem areas to improve efficiency and limit downtime.

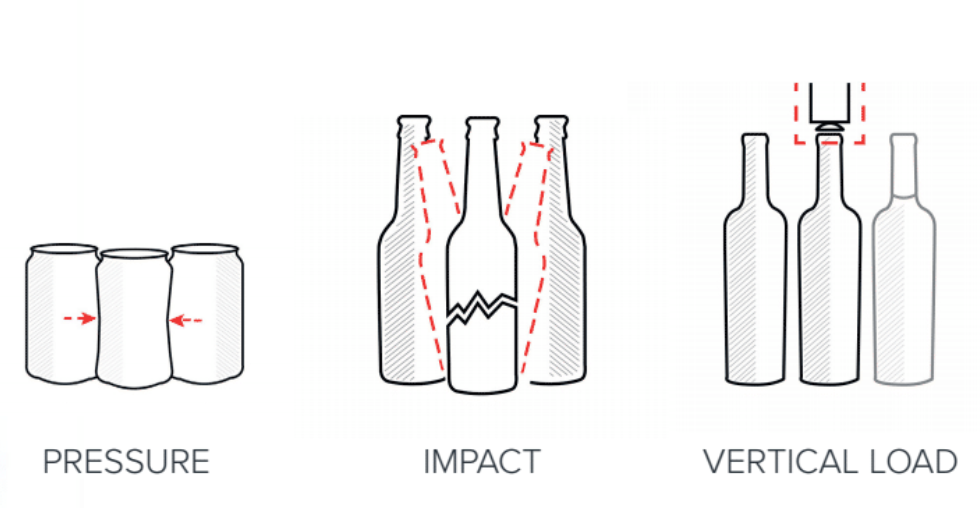

• Pressure

• Impact

• Vertical Load

Pressure

High levels of pressure on conveyors can compact containers, resulting in costly aesthetic damage such as label tearing and crush damage.

Pressure, and related mechanical variables such as spin, tilt and friction, cause scuffing and abrasion damage by compacting containers. Damage to the container can range from label tearing and decoration damage, to loss of UPC to catastrophic failure.

High pressure doesn’t only affect the container. Sustained pressure increases equipment wear, the frequency of downtime events and maintenance cost on all type of filling lines.

All filling lines will benefit from a reduction in pressure.

Pressure occurs throughout the transportations systems of all filling lines and a well-balanced line is needed to optimize the line’s overall performance. Regardless of the container material – glass, aluminum or PET – packaging operations are well served to monitor pressure and correct areas of concern.

Common causes of pressure include:

• Line design

• Control strategies

• Conveyor belt wear

By monitoring pressure within a weekly or bi-weekly maintenance program, operators can take immediate action on areas of pressure that are outside of specification and prioritize future maintenance tasks when trends indicate an escalating issue.

Quote call out: ‘Did you know? Pressure and friction is the primary cause of damage to aluminum and PET containers.’

Impact

Impact is a particularly damaging force when processing glass containers and while It isn’t a guarantee that breakage will occur simply because a bottle receives a given impact, the probability of breakage will increase.

Understanding the root cause of shock in production, measured in Inches Per Second (IPS), enables fillers to improve line efficiency and reduce container damage. In the simplest terms, the IPS rating of a bottle means that a bottle is certified to have a given percentage of breakage when it is impacted by a known mass.

IPS (Inches Per Second) measurement has long been a strength rating for glass bottle producers but unknown to fillers. Today, IPS is fast-becoming a vital measurement tool for fillers trying to design and process a lightweight bottle design without reaching a breaking point (literally) where it cannot withstand the impact it receives on a given line.

The real world is a complex environment with diverse variables that affect how a container responds to impact. For example, when a container goes through the filling line it receives multiple impacts of varying intensity. With the aid of smart in-line sensors, fillers are now able to measure IPS dynamically on the line and use measurement tools such as the Vidrala Impact Index to rate a line’s impact performance.

Vertical Load

Improperly calibrated corking, capping and sealing machines can put excess downward force on containers and cans causing neck damage and breakage that operations can’t afford, while over-stacked pallets trigger seal failures that affect product quality.

Calibration is time consuming. Most capper machines average over twenty-four heads, and on lines where more than one container is filled, calibrations need to be performed every time a bottle type is switched.

Capper and seamer machines are typically preset to achieve a proper seal on the container being processed. In reality, it is difficult to measure the force applied to the container for each head, as compared to the setting. Given the ramifications of improperly calibrated heads, it’s important to understand this difference in applied forces.

Common causes of excess vertical force:

• Improper calibration

• Over-stacked pallets

In-line sensors provide immediate and real-time measurement of the vertical force that each capper head is pressing onto the container. Fillers can often reduce calibration from hours to minutes.

Vertical load is an important factor to measure to ensure product quality. An excess force can cause neck damage and downtime while insufficient force will result in an improper seal.