I was recently in a sales call where another vendor was pitching a data tool to the CEO and an experienced technical team lead. During the pitch, the technical team lead was dubious because he felt that he already had the answers about what was happening on his line and didn’t require data to tell him what he already knew.

The CEO intervened, asking “Do you think that a new employee would know the same things that you do about our line?”

“No, of course not,” responded the technical lead, “This might be a great tool to help them.”

The 1-hour line check

Imagine a slow-motion replay of an awesome play during a sporting event. Just like your line, things move so fast that you don’t always see exactly what happens. Hence the need for a slow-motion replay and stats to back up the play. Think of a quick line check as just that – a way to capture what you can’t always see.

A full technical audit is performed by an auditor, engineer or subject matter expert that evaluates deficiencies or areas of improvement in a process, system or proposal. And while sensors are a great tool that are used by many auditors – at Masitek, our sensors are most often used by in-house teams to quickly prove or disprove an issue and then as a regular weekly check as part of maintenance routine.

Lately, we’ve been performing quick line checks for beverage companies around the world and the response to instant information in an easy to understand and correlate format has been very well received.

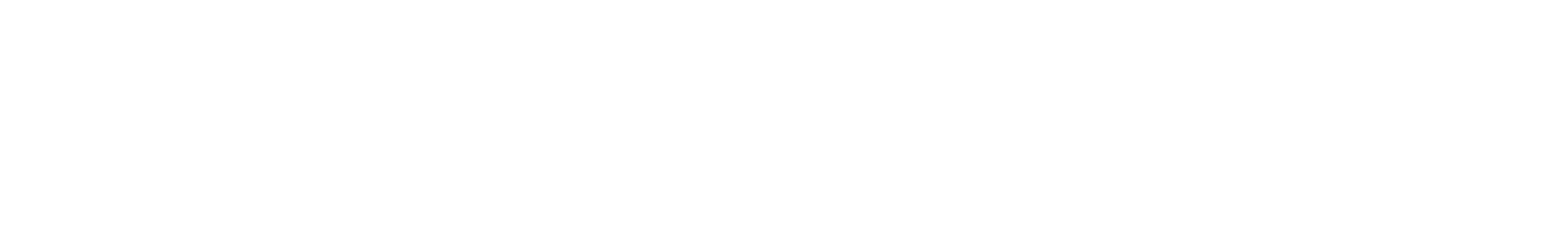

Take a look at how a 1-hour line check detected areas of high shock and pressure for this beer producer. *Names changed.

ABC Bottling

• ABC Bottling Location has a few areas of concern with one line.

• A 1-hour audit was performed on the line in question, a total of 19 data runs in four areas were conducted

• Measurements studied included Impact, Pressure and Scuffing.

• Two areas of concern were identified during the audit:

– Area C to Area D – Medium to high pressure and high scuffing

– Area E to Area F – Very high pressure and high scuffing

AREA A TO AREA B

Two runs were performed and in both runs we encountered medium pressure and scuffing.

The run shown on top detected hot spots near the entrance of a particular machine. The run at the bottom show them closer to another key machine. A few medium impact areas were found as well.

No major areas of concern.

AREA C TO AREA D

5 runs were performed in this area as we detect issues in the corner resulting in medium to high pressure and high scuffing.

AREA E TO AREA F

3 runs were performed in this area due to very high pressure and scuffing areas.

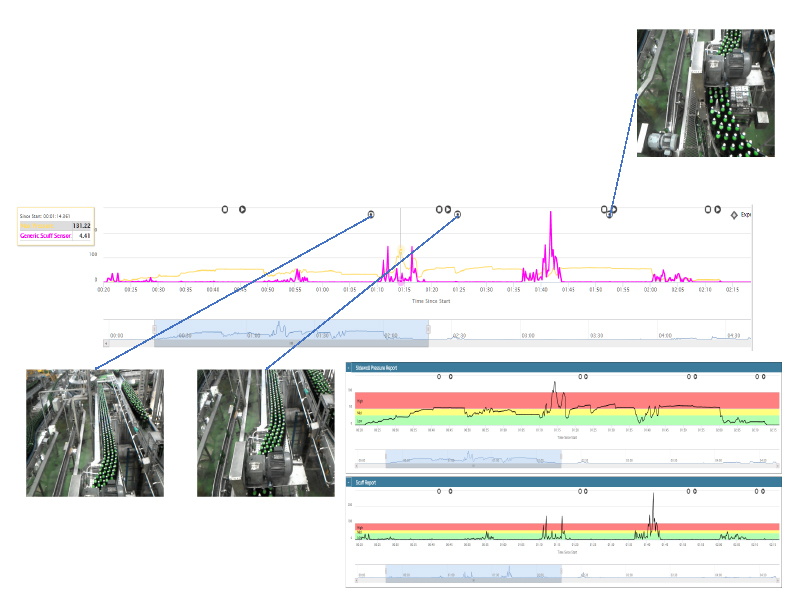

LABELLER

Though high impact areas were found, the magnitude of the impact is not as high as experienced in other plants. No major areas of concern.

Conclusion

The highest priority should be to fix the 90-degree bend in Area C and the Area E to Area F specifically closer to the Area F intake.

More in-depth analysis should be done to pinpoint the source of high pressure, scuffing and impact areas. Different scenarios (emergency stop, full conveyor belts, different location of sensor, …) should be run as part of the in-depth analysis.

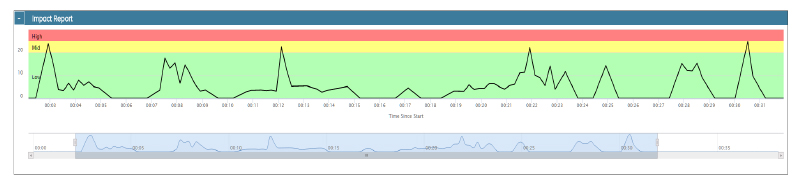

Detailed analysis, Filling Line XX

It isn’t that the technical team lead didn’t know his line, quite the opposite – but when you can SEE and share the real levels of pressure and scuff that your products are subjected to, in graph format on your tablet, measured by the millisecond on the line – it’s concrete evidence that either your line is as efficient as possible or that there is work to be done in this specific area. It just isn’t possible to have this level of information without a sensor whose data can be replicated and compared.

A 1-hour line audit once a month (when combined with weekly checks) makes pinpointing problems becomes so efficient it is no wonder that the top ten bottling and canning companies in the world have already deployed in-line sensor replicas as part of their maintenance routine.