As we’ve established, the Vidrala Impact Index is an exciting new tool for fillers to rate their line’s impact performance. This post shows you how to measure VII using smart in-line sensors.

First, let’s start with impact measurement in general:

Impact magnitude is typically reported in IPS (Inches Per Second). IPS represents the speed of the hammer of an impact tester (more on that below) when it impacts the container.

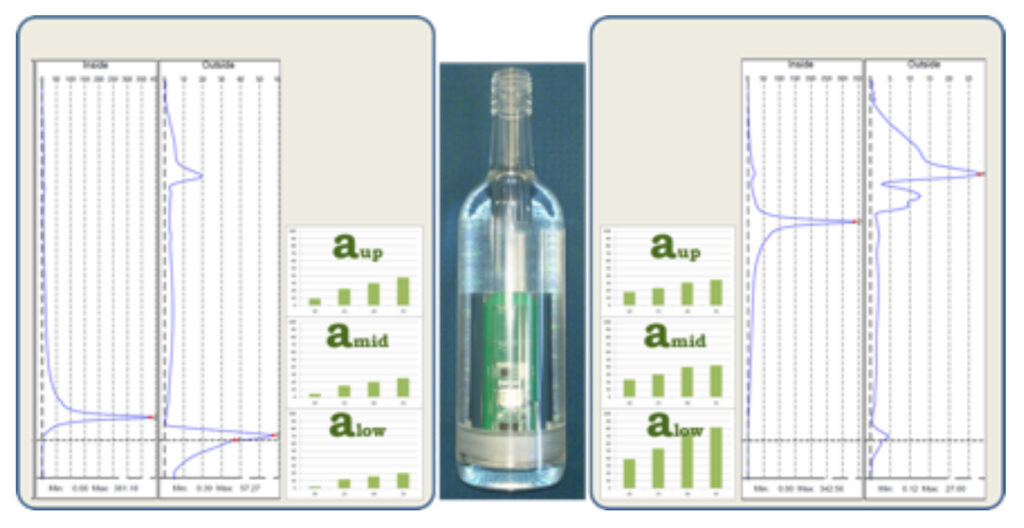

With the use of smart in-line sensors such as ShockQC, this measurement is based on the information provided by the various accelerometers integrated in sensor which are embedded in a container replica.

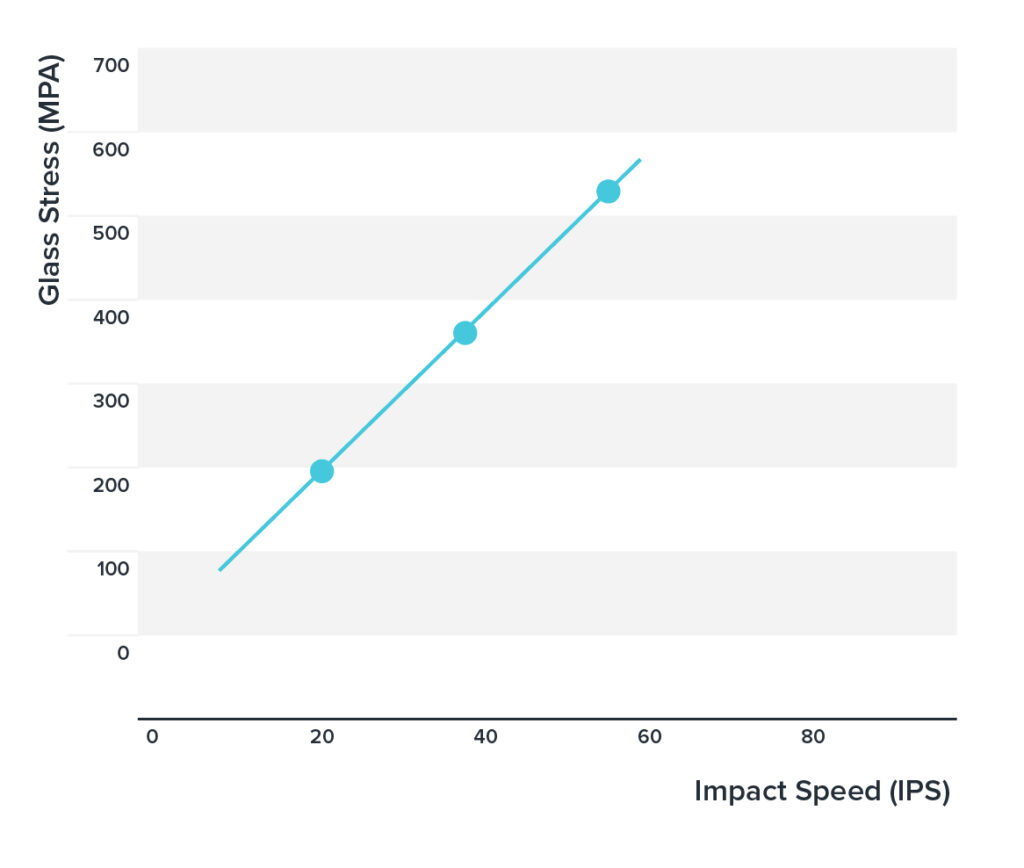

The correlation between accelerations and IPS is done by means of a laboratory calibration. As shown below, the correlation between impact speed and acceleration is linear. As such, the calibration of the ShockQC device is very reliable and straightforward.

Glass Stress vs. Impact Speed

Glass stress relates to impact speed

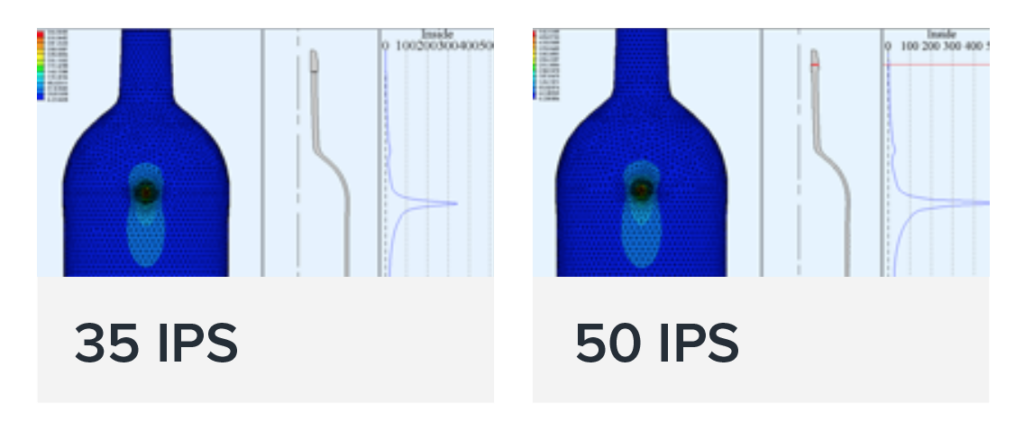

An impact tester is the standard tool used by glass manufacturers to measure the impact strength of the glass containers they produce.

The device consists of a calibrated pendulum hammer that strikes the bottle in its sidewall against a V-shaped backstop. Providing the pendulum arm with a bigger initial angle, increases impact velocity.

Typically, the graduated scale to adjust this angle shows both energy and speed units. However, only the speed unit is used by glass manufacturers as the stress induced in glass is linear with speed. Hence, it is much more appropriate when using it for a strength measuring purpose.

ShockQC registers accelerations at different heights including heel and shoulder.

As shown below, accelerations are proportional to impact speeds for both upper and lower contact tests performed with the impact tester. Depending on the ratios between the acceleration at different heights, the appropriate correlation factor is applied to convert Gs into IPS.

Converting IPS to the Vidrala Impact Index

The Vidrala Impact Index represents the number of impacts, with the same IPS rating of the bottle, that would produce a similar breakage probability.

Using algorithims that have been developed and tested against real-world conditions, ShockQC is now equipped to calculate VII for both individual or multiple impacts. For multiple impacts, the individual impact indexes are added up to obtain the overall index. Using this approach, the index can be applied against the entire filling line, or sections thereof.

It is recommended to establish a minimum threshold for relevant impacts to be included in the calculation. The reason for this is that a very large number of them could not be considered independent from each other any more. The overall contribution of these weakest impacts should be considered negligible. We recommend to use 15 IPS as the minimum impact magnitude to be considered.